TACKLING E-WASTE:

MODULAR AND REPAIRABLE APPLIANCE DESIGN

University Design Thinking Course.

Group Project, 2023.

BRIEF

Working in a team of 4

Select a ‘wicked problem’; we chose the issue of e-waste.

Utilise design thinking and human-centred design methodologies such as rapid iteration, prototyping, co-design, and user research to develop an output or solution for the chosen problem space.

OUTPUTS

Modular toaster design, designed to be fixed instead of replaced.

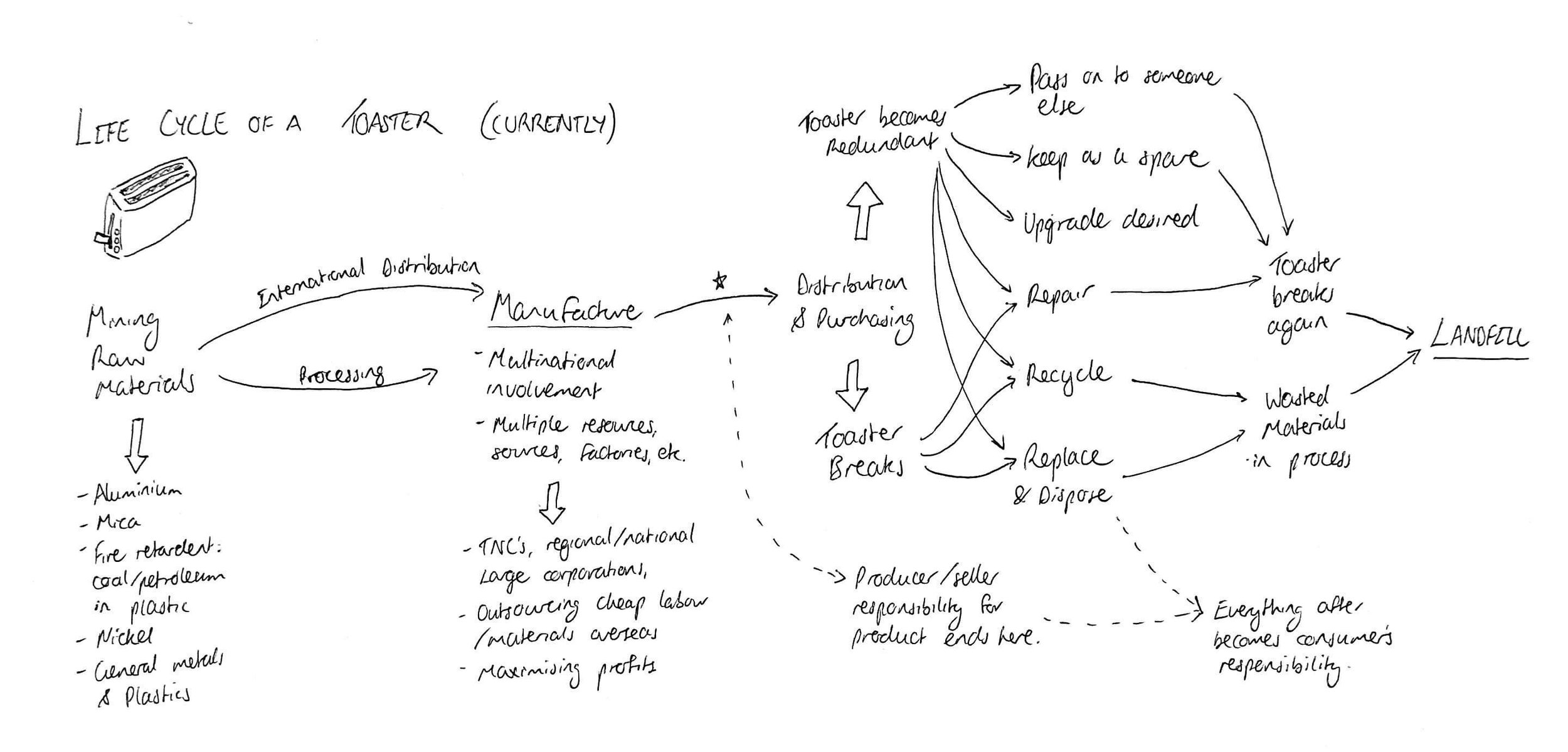

Circular business model founded on repairability, recycling and recapturing value from products at their end-of-life to offer an alternative to the ‘cradle to grave’ norm in appliance design.

Speculative legislation design.

E-Waste is the fastest growing waste stream globally.

But where do we intervene in such a complex issue?

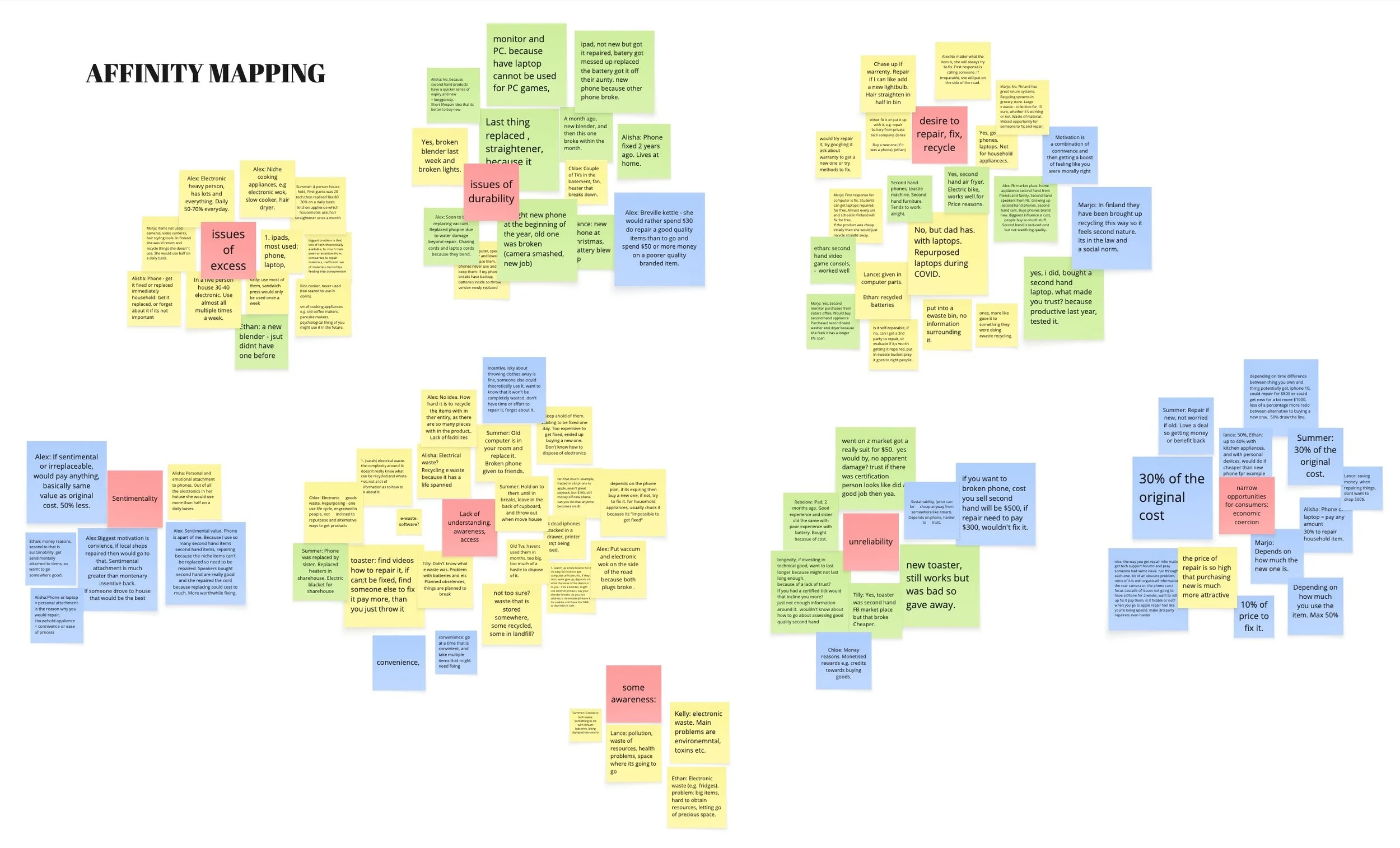

USER RESEARCH:

Surveys and synthesis of findings.

PROBLEM IDENTIFICATION

Small household appliances:

Neglected area in the e-waste issue

High repair costs

Cheap replacement costs

Lack of opportunities for recycling

Status quo of ‘design for disposal’ within the industry

PROBLEM STATEMENT

With a focus on small household appliances, how might we alleviate the e-waste problem by changing consumer habits and mindsets, increasing product durability, and reimagining the product lifecycle?

IDEATION

LOW FIDELITY PROTOTYPING

USER TESTING

Collecting feedback, design iteration.

HIGH FIDELITY PROTOTYPING

3D PRINTING

Self-taught Fusion360 software for 3D modelling and printing.

FINAL DESIGN

DURABILITY

Hot plate style heating instead of wires

Base opens to release crumbs

Simplified user interface

LONGEVITY

Entirely modular: broken parts can be individually replaced without forsaking entire unit

Changeable colour case to evolve with owner’s preference

CIRCULAR BUSINESS MODEL

Illustrates how an appliance company could recapture value from old products returned by customers.

Increasing ease and accessibility for consumers to repair and properly recycle their appliances.